~REMOVAL~

SAFELY REMOVE YOUR ANTIQUE TIFFANY & CHURCH STAINED GLASS WINDOWS

Listed below are the general steps for a typical stained glass window removal for the average DIY-er. Though it is possible to perform a removal on your own, please note that one small crack during a removal attempt could result in the loss of thousands of dollars in value. We would recommend using a company like ourselves who have removed thousands of antique church stained glass windows of every caliber; from inexpensive home windows… to record-breaking-sale Louis Comfort Tiffany windows.

~Q & A~

Q: “What are the risks involved in removing an antique stained glass window without the aid of a professional?”

A: Antique stained glass window removals always have their quirks because no 2 windows were installed the same way. They can be tricky and, without the right experience, can lead to mishaps such as cracks and bowing, which in-turn will lead to a major devaluation of the window’s overall worth. There is some merit in performing your own stained glass window removal, and, depending on your skill level, quite possible; however, the risk can easily outweighs the reward. Even the slightest hairline crack that forms through a face, hand, feet, etc of a figural window can devalue the window by $1,000 or more instantly due to refabrication costs of the newly-broken piece. Furthermore, the window will now be even less valuable since the new face, hand, feet, etc will be unoriginal to the rest of the antique glass. Even the smallest border glass crack would need to be repaired in a stained glass repair shop at a labor rate of around $50/hr.

Q: “How can JDT Studio aid in my window removal?”

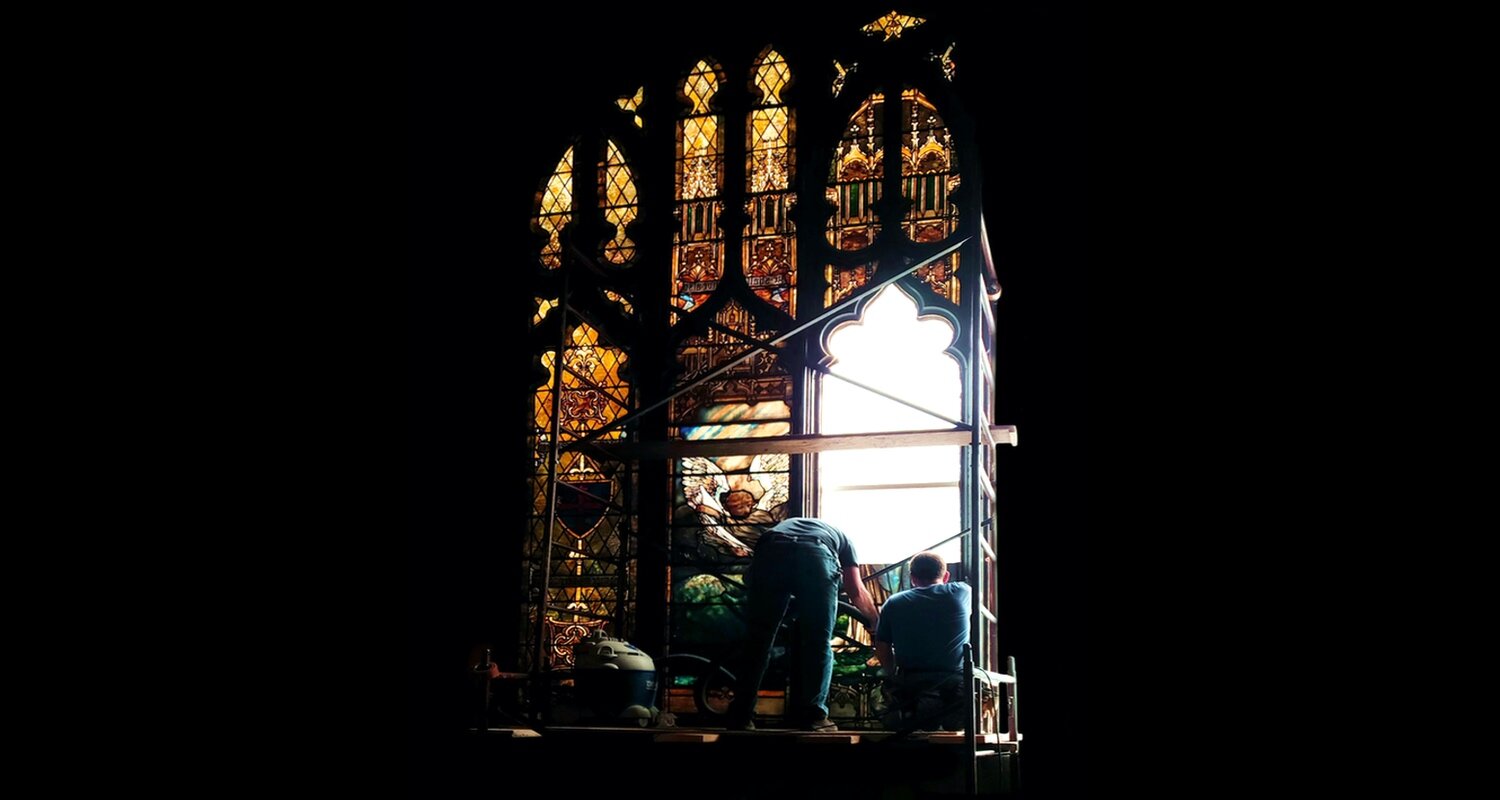

A: JDT Studio has extensive resources and experience to remove any number of windows for you… safely. Our team has dealt with all sorts of unseemly window removals; from frail windows that literally fall apart in your hands… to overly-secure windows welded directly into a steel frame that require the use of a 7” industrial Dremel blade hovering at 4,000-RPMs just 10 centimeters above a 1/3rd million dollar window to free the panels. Talk about nerve-racking, but JDT pulled off both jobs (and countless others) without a hitch.

~WINDOW REMOVAL (step-by-step)~

Step 1:

REMOVE the stops

Using a wide, flat tool such as a putty knife, wide chisel, or flat multipurpose knife, gently pry the wood stop away from the wood frame on all sides, being sure to note which stop needs to be removed first. The first stop to be removed will always be the stop that you can clearly see is not being hindered by another stop holding it in. While prying a stop up, use small amounts of equal force along the entire piece of wood, repeating as necessary until the stop is free.

Step 2:

SCRAPE the resin

Once all stops have been removed, there will typically be a type of dried resin, or caulk, holding the window’s border lead in place. If the resin is loose enough, feel free to use the multi-purpose knife’s pointed edge to carefully scrap it out. Be sure to have adequate ventilation as well as a respiratory mask, gloves, and other protective coverings as the resulting dust may contain asbestos or lead particles. It can be extremely dangerous to undertake this sort of project without taking all of the proper safety precautions.

Step 3:

DECIDE about the rebar

In most cases, especially with larger stained glass windows, there will be a steel re-bar [“reinforcing bar”] holding the window in place, which is designed for weight distribution in order to prevent sagging. If you are lucky, the bar will only be built into the stops, which would mean that the bar became free once the stops were removed. Unfortunately, that type of a removal is the exception to the rule and most bars are embedded deep into the wooden frame itself. If you need to save the frame, the only option is to sever the copper wires that attach the bar to the window and then Dremel the steel bar in half so that it can slide out from both sides of the frame. Note that this will put the window in grave danger as one slip with the Dremel could shatter the window. The alternative option would be to chisel into the wood frame around the bar’s location, allowing the bar to slide straight out with the window. Obviously the latter method will damage the frame as well as put the glass at risk since the pressure caused by chiseling out the wood will subsequently put pressure on the bar which will ultimately put pressure on the glass and possibly crack or shatter it.

Step 4:

PULL the nails

Using a small lady foot pry bar, cautiously pry out the nails holding the border lead in place. To avoid damage, it is essential that you only pry against the remaining border lead, but only with a certain degree of force as the border glass is located inside the border lead and can crack very easily.

Step 5:

LOOSEN the glass

At this point, due to the expansion of the wood over the years, the panels will still be tight. Once the wood stops, caulk, and nails have all been removed, you will need to either grab the bar or [if you’ve already removed the bar] grab the bar’s remaining copper wires and begin to gently rock the window out by pushing and pulling the window in and out at a slow-yet-steady pace. The remaining debris should start to come loose and the window will start to loosen. If no good handhold is available, an industrial glass suction cup can sometimes be mounted on the panel and used to help provide leverage. In any situation, be careful to pull only with the appropriate amount of force as pulling too hard while the window is still caught on some caulk or on a nail will result in damaged glass, while pulling too softly will yield no movement at all.

C L I C K A S E R V I C E :

C L I C K A P R O J E C T :

ANTIQUE TIFFANY CHURCH STAINED GLASS WINDOWS & ARCHITECTURAL ITEMS

PRESERVE HISTORY WITH JDT STUDIO BY BUYING, SELLING & RESTORING ON THE LARGEST, MOST TRUSTED, ANTIQUE STAINED GLASS & ARCHITECTURAL WEBSITE